Shipping costs can make or break your ecommerce business, and one hidden culprit that often drives up expenses is weight discrepancies. If you’ve ever been surprised by an inflated shipping bill, chances are, improper packaging is to blame.

But don’t worry, this guide will walk you through how choosing the right packaging can significantly reduce weight discrepancies and keep your ecommerce shipping costs under control.

How Simple Packaging Mistakes Can Lead to Weight Discrepancies?

Even minor packaging mistakes can lead to significant shipping cost discrepancies. Understanding the mistakes is the first step toward preventing them. Here are some common errors and their impact:

1. Inappropriate Packaging

- Overuse of Packing Materials: Excessive bubble wrap or filler materials increase volumetric weight unnecessarily. For instance, a small electronic item wrapped in layers of foam and placed inside a large box can significantly raise shipping costs.

- Weak Packaging: Thin or flimsy boxes can lead to bends, irregular shapes and damaged products, resulting not only in costly returns and replacements but also increased volumetric weight leading to higher shipping charges. A brittle box carrying fragile glassware may not withstand shipping stress, leading to cracks or breakage.

2. Choosing the Wrong Box Size

- Using a box larger than necessary inflates the volumetric weight, increasing shipping costs. If a small item is placed in a large box with excess filler, you’ll be charged for the space rather than the actual weight.

- Unnecessarily large packaging also takes up more space in courier vehicles, which can lead to additional fees. For example, an apparel brand using unnecessarily large boxes, instead of flyers for T-shirts could be paying higher shipping fees than necessary.

3. Irregularly Shaped Products

- Products like shoes or oddly shaped items, when packed improperly without boxes or untapped flyers, make it harder to measure weight and dimensions accurately often leading to unexpected charges. For example, a pair of sneakers packed without a proper box or in flyers without taping may get an inflated volumetric weight due to inefficient space usage.

- Some products may have slight weight variations due to manufacturing differences. If packaging materials aren’t adjusted accordingly, it can lead to discrepancies in expected versus actual shipment weight.

4. Lack of Standardized Weighing Practices

- Uncalibrated weighing systems can produce incorrect weight data, which shipping carriers use for billing. A scale that isn’t calibrated correctly could lead to discrepancies that add up over multiple shipments.

- Small discrepancies add up, leading to weight disputes and increased operational costs. If every package in a bulk shipment is slightly off, the cumulative cost difference can be substantial.

By addressing these simple mistakes, ecommerce businesses can ensure accurate shipping weights, avoid unnecessary costs, and reduce disputes with courier partners.

Packaging Strategies to Prevent Weight Discrepancies

The key to reducing these weight discrepancies lies in accurate weight measurement and proper packaging techniques. Here’s how:

1. Measure Weight Accurately

- Always calculate both dead weight and volumetric weight using the formula: (L × B × H) / 5000.

- Include packaging materials in your weight calculations to avoid underestimating weight.

- Example: A cosmetics brand shipping skincare products should factor in the weight of the product container, protective packaging, and the outer box to get an accurate reading.

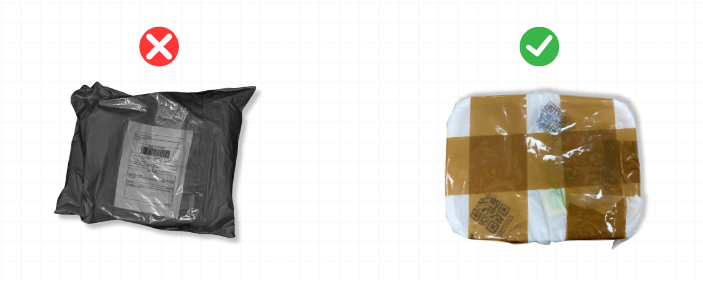

2. Use Proper Packaging

- Choose durable 5-ply boxes to prevent bending or damage during transit. A D2C electronics brand shipping smartphones should use sturdy boxes with anti-static padding.

- Use boxes that match the product size and avoid oversized packaging. For example, a jewelry store can use compact, cushioned packaging instead of a large box.

- Ensure irregularly shaped products are properly secured with suitable padding inside the box. A furniture brand shipping a custom chair should use custom-fit boxes to avoid extra space charges.

3. Maintain Records and Conduct Equipment Checks

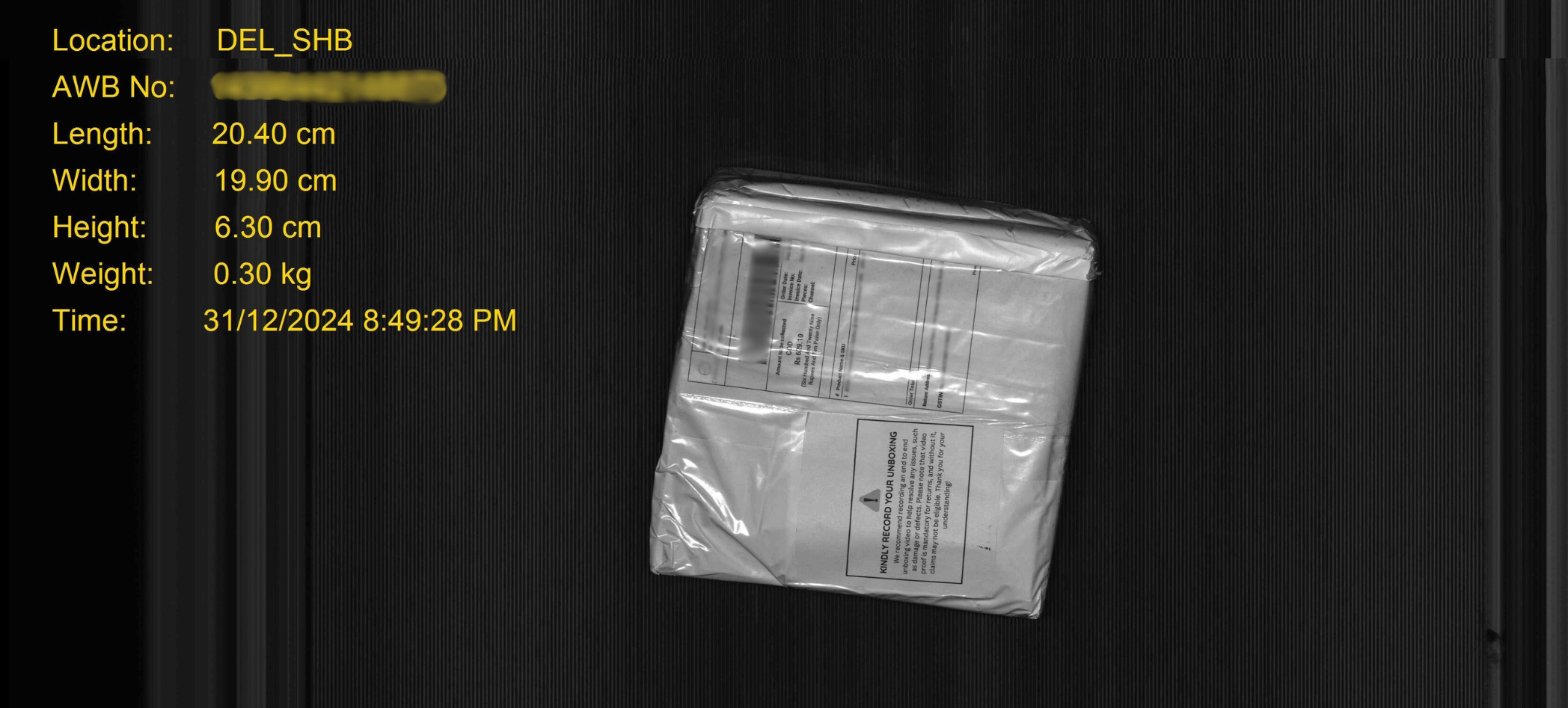

- Take images of packages showing both dead weight and volumetric weight, similar to that of sorter images. If a courier charges an extra weight fee, having an image of the package’s actual weight can help in disputes.

- Regularly calibrate weighing scales to ensure accurate weight measurements. A logistics company that handles bulk shipments should check its weighing systems weekly.

4. Map Packaging to SKUs

- Assign appropriately sized boxes based on SKU dimensions (length, breadth, and height) to reduce weight discrepancies. A fashion brand selling shoes can map each SKU to a corresponding box size for consistency.

- Use a standardized packing guide for different product categories to maintain uniformity. This is especially useful for businesses shipping multiple product types.

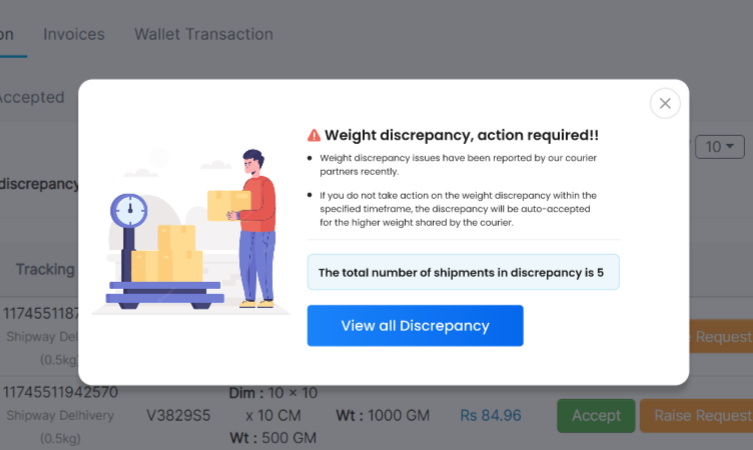

5. Validate Courier Charges

- Cross-check courier charges with internal shipment records to detect and dispute discrepancies promptly. For example, if a shipment was marked as 10kg but your records show 8kg, you can raise a weight dispute.

- Maintain a log of weight discrepancies for quick resolution. If a courier routinely overcharges on weight, historical data can be used to challenge the fees.

Pro Tips to Avoid Weight Discrepancies

- Document package images to support billing dispute resolutions.

- Conduct regular packaging audits to identify high-risk products that may lead to weight discrepancies.

How Shipway Helps Reduce Weight Discrepancies?

Shipway provides reliable logistics support and tools to ensure accurate weight measurement and transparency in billing. Here’s how Shipway minimizes weight discrepancies:

1. Image Verification

- Compare sorter images with Airway Bills (AWB) to validate dimensions and weights before shipment. This can help prevent billing disputes with courier services.

2. Historical Weight Tracking

- Access past shipment data to track and maintain consistency in weight measurements. For example, if a certain SKU always results in a weight discrepancy, you can adjust packaging accordingly.

3. Product Content Verification

- Ensure that the shipment’s content, SKUs, and quantities match the provided data for accurate billing. This is particularly useful for ecommerce brands dealing with large inventories.

4. Sample Image Verification

- Verify sample images of SKUs or similar products to ensure accurate weight and dimension assessments. This helps businesses validate weights before dispatch.

5. Quick Dispute Resolution

- Submit weight disputes via the Shipway dashboard within 7 days of identifying a discrepancy.

- Resolutions are typically provided within 72 hours, with escalation options available.

6. Dedicated KAM Support

- All ecommerce businesses with 100+ orders per day using Shipway get a dedicated Key Account Manager (KAM). Your KAM will assist in reviewing and comparing sorter and sample images. This ensures faster issue resolution and improved shipping efficiency.

Wrapping Up

Proper packaging isn’t just about protecting your product, it’s also about ensuring accurate weight measurement and reducing shipping costs. By implementing the right packaging strategies and leveraging shipping automation solutions like Shipway, which provides dedicated KAM support and weight waivers you can minimize weight discrepancies, avoid overcharges, and improve your bottom line.

Start optimizing your packaging today and keep those shipping costs in check!

You may also like…

Top 10 India Delivery Company for E-commerce Businesses (2026)

Choosing the right India delivery company is crucial for eCommerce businesses looking to provide fast, reliable, and cost-effective shipping. The...

read more10 Fastest eCommerce Courier Partners in India for 2026

Finding a fast delivery service in India has become essential for every growing eCommerce brand. With customer expectations rising rapidly, online...

read moreTop 10 Logistics Companies in India for eCommerce (2026 List & Guide)

Introduction: Why Logistics Matters for India’s Growing eCommerce Sector The Indian eCommerce sector has witnessed tremendous growth, projected to...

read more